Foamtech Antifire company conforms to all the national and international approvals, certifications and guidelines

Ranger Pre-Engineered Fire Suppression System

Introducing FOAMTECH®’s swift response pre-engineered fire suppression systems, a dynamic fire suppression solution that combines advanced technology with functional simplicity to keep what’s precious and safe. FOAMTECH® Pre-Engineered Fire Suppression Systems protect operation-specific critical assets and equipment from fire. Our systems are pre-engineered, self-contained, standalone, and require no power for activation.

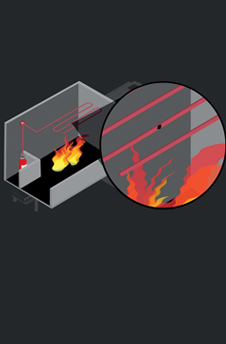

The most groundbreaking feature of the system is the specially designed heat-sensitive pneumatic polymer detection tubing. It is connected at one end to a FOAMTECH® extinguishing agent container, while the rest of it runs unobtrusively throughout the area at risk. When the flame comes in contact with the heat-sensitive tubing and reaches a temperature of 110°C to 138°C, the tubing bursts open at that exact spot and forms a miniature nozzle. The pneumatic mechanism triggers the valve of the extinguisher and sprays the extinguishing agent out of the tube directly onto the flame, annihilating the fire instantaneously.

Product Features

Applications

- Pneumatically Operated

- Electronics Friendly

- Simplified High Risk Protection

- 24-Hour Protection

- Flexible Detection Tubing

- Rugged Design

- Residue-Free

- Cost-Effective

- Airports

- Metro Rail

- Telecom

- Building

- Automotive

- Oil & Gas

- Pharmaceutical Industries

- MFG. Plants

- Mining

- Marine

- Container

- Depot

- Power

- Renewable

- Energy

Direct Low Pressure DLP Clean Agent System Unit

PRODUCT OVERVIEW & PRINCIPLE OF OPERATION

FOAMTECH® DLP—Direct Low-Pressure Clean Agent Systems are primarily a pre-engineered automatic fire detection and suppression system utilizing various low-pressure clean agents, i.e., HFC227ea, Novec1230/FK-5-1-12.

The FOAMTECH® Linear Pneumatic Fire Detection Tubing (LP-FDT) is installed and connected to the DLP Valve and routed throughout the protected hazard area/enclosure. The primary function of the Pneumatic Fire Detection Tube (under pressure) is to detect heat/fire and activate the valve for discharge of the agent by rupturing at the hottest point along its installed length on flame impingement. On rupture, a nozzle is formed at the burst point.

The cleaning agent under pressure in the cylinder then flows out through the burst point, distributing the cleaning

Direct Low Pressure DLP Clean Agent System Unit.

Indirect Low Pressure ILP Clean Agent FKS-1-12 System Unit

PRODUCT OVERVIEW & PRINCIPLE OF OPERATION

FOAMTECH® ILP-Indirect Release Low-Pressure Clean Agent Systems are primarily a pre-engineered automatic fire detection and suppression system utilizing various low-pressure clean agents, i.e., HFC227ea, Novec1230/FK-5-1-12, FE36, etc.

The FOAMTECH® Linear Pneumatic Fire Detection Tubing (LP-FDT) is installed and connected to the ILP Valve and routed throughout the protected hazard area/enclosure. The primary function of the Linear Pneumatic Fire Detection Tube (under pressure) is to detect heat/fire and activate the valve for discharge of the agent by rupturing at the hottest point along its installed length on flame impingement.

On rupture due to loss of pressure in the tube connected to the valve, the pressure from the top assembly of the ILP valve is released (can be done by both automatic or manual activation), thereby the internal piston slides to its fully open position, allowing the pressurized clean agent to travel through any or a combination of three outlet ports via delivery hose/pipes and discharge out from the fixed nozzles within the protected area, flooding the entire area with the agent and suppressing the fire instantly.

Note: To assist annunciation, both direct & indirect low-pressure systems can be connected to FACP through an optional pressure switch & potential-free contact arrangement.

Listing & Approvals:

UL Listed Foamtech Fire Detection Tube

UL/FM/EN-approved suppression agents

Filled in UL-listed & PESO-approved fill plant

CE-Approved Cylinders

Overall system in CE approved

The system is in compliance with NEPA: 2001 (Edition 2015—latest).

Kitchen Fire Supression System

The risk of fire hazard proves to be very dangerous in the modern electrical & gas-operated domestic & commercial kitchens. Fire in the kitchen is generally due to the burning of oil. However, oils & fats burn at relatively high temperatures, and hence, once they catch fire, extinguishing them is very difficult.

With the aim to protect modern kitchens from such risks, FOAMTECH has developed the Foamtech Automatic Pre-Engineered Fire Suppression system according to the NFPA & UL Standards. It can be widely used in the kitchens of the hotels, institutes, restaurants, and schools, etc.

How Does the System Work?

The hood is covered with the pneumatic Heat Sensing Tube (HST). On coming into contact with fire, HST burst open at a predetermined temperature.

This leads to a drop in pressure, which signals the indirect valve, thereby activating the system. The strategically placed nozzles disperse the extinguishing agent evenly over the entire cooktop area, ensuring no blind spots during firefighting.

Key Components of the System

Applications Areas

- Cylinder&Valve Assembly

- Extinguishing Agent

- Heat Sensing Detection Tube

- Master Control Unit (MCU)

- End of line adopter with pressure gauge

- Discharge nozzle

- Tee, Elbow, Connectors

- Discharge piping

- Manual actuation unit

- Anti-tempered seal

- Hotels

- Restaurants

- Hospitals

- Schools

- Public Institutions

Fire Extinguishing Agent: EN Approved FOAMER Brand Kitchen Fire Chemical type foam

Listing & Approvals:CE Certified Foamtech Kitchen Fire Suppression System

EN certificated Agent K Foam

UL Certified for the detection tube.